| Sign In | Join Free | My xpandrally.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My xpandrally.com |

|

Brand Name : S&G

Model Number : S&G-C Purlin

Certification : ISO:9001

Place of Origin : China

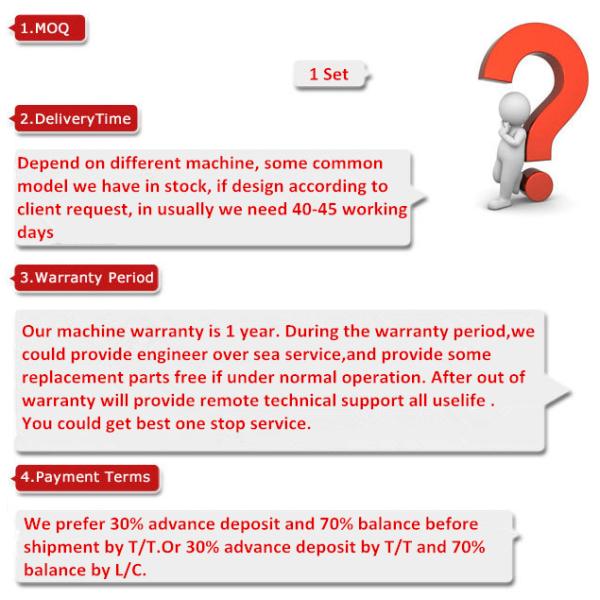

MOQ : 1Set

Price : Negotiation

Payment Terms : T/T or western Union

Supply Ability : 600Sets per year

Delivery Time : 90 working days after received your payment

Packaging Details : Nude

Model No. : S&G- Wall Angle Bar

Tile Type : Colored Glaze Steel

Use : Wall

Production Capacity : 10-15m/min

Power(W) : 4+4KW

Dimension(L*W*H) : 11mX1.3mX1.35m

Weight : 3.2T

Raw material : Galvanized Steel Sheet

Thickness : 0.3--1.2mm

Control System : PLC with touch screen

Way Of Drive : Gear or Chain

Cutting type : Hydraulic cutting

Automatic Bare Steel Wall Angle Light Gauge Frame Roll Forming Machine,wall corner bead angle iron roll forming machine

Summary of wall angle machine

1). To design and make the best roll forming machine, we took EUROPEAN quality standard;

2). Choose the best material and components, and adopting our 1 0 + years experience ;

3). We achieves that the machine capacity is double of the competitors;

4). The machine working speed can be 60m/min ;

5). Very easy to install and operate the roll forming machine.

Machine working flow of wall angle machine:

Machine Technical Specifications of wall angle machine:

About raw material and product for roll forming machine

| Material &product | Feeding width | according to profile |

| Effective width | according to profile | |

| Raw material | galvanized steel strip | |

| T hickness | 0.3-0.7 mm | |

| Yield strength | 280-350 MPA |

Decoiler

| Manual decoiler | Inner diameter:450-550mm | Expand by band |

| Outer diameter:1500mm | ||

| Max Coil width :30 0mm | ||

| Capacity: 1.5T | ||

| Decoiler dimension:1.5 *1.5*1.5m | ||

| Decoiler weight:355KGS | ||

| Quantity: 1set | ||

| Usage: It is used to support the steel coil and uncoil it in a turntable way. Passive uncoil pulled by roll forming system | ||

What the main forming machine →as below

| Main Forming machine | Forming steps | 12 steps |

| Shaft diameter | 50mm | |

| Machine stand | Individual Arch Plate | |

| Machine frame | steel plate welded | |

| roller material | Cr12 | |

| shaft material | 45# steel with quenching and tempering | |

| Work speed | standard: 20---25m/min; 45---60m/min | |

| Transport | By gear | |

| Power of main machine | 4kw | |

| Voltage | 380V-50HZ-3P(as required) | |

| Machine dimension | 5.5*0.8*1.5m | |

| Machine weight | About 2.5T | |

| Machine color | Yellow and blue(as required) | |

| Usage: In order to keep the product shape and precision, adopts welded sheet structure, motor reducer drive, chain transmission,roller was chromed which can keep the molding plate surface smooth and not easy to be marked when it is working Feature : Ensure stability , precision and lifetime. | ||

|

|

Fully Automatic Steel Roof Roll Forming Machine , False Ceiling Channel Making Machine Images |